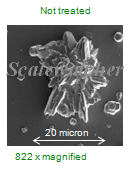

Water containing dissolved minerals and mineral crystals with sharp edges. Easy to adhere to pipe walls.

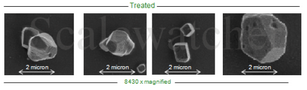

Pictures taken by an electron microscope

Scaling is caused by a lot of different effects - the most impor-tant being - super saturation, which is essential. It is not the Calcium ions in the solution, but the carbonate hardness, that is the Ca(HCO3)2, that is forming scale.

Electronic and magnetic scale removal devices alter the num-ber, size and shape of the crystals to reduce adherence and deposit buildup on the pipe wall. This is achieved in two dif-ferent ways:

The treatment influences the initial nucleation, resulting in crystals that do not "stick" together. While untreated water builds up matted structures, that grow more and more, Scalewatcher treatment creates idiomorphic, scattered crystals, that will not form matted structures. They have a roundish shape, which means, that they have a rather big volume in relation to a rather small surface. This feature makes them sensitive to water currents and they will be flushed out of the pipe easily..

According to the latest scientific works, colloidal clusters in water may have positive and negative charges (Janus model) at different places. There is only little energy needed to re-position the colloids, if an electromagnetic field with the correct frequency is used. Once these colloids have been repo-sitioned, their tendency to "stick" somewhere is much lower.

The overall effect is that crystals will not adhere to pipewalls and will be carried away with the water flow.

The removal of existing scale follows different aspects:

The scale surface to water follows like any process at a boundary between two substances the law of mass action, which means there is an action and a reverse action of the same kind. In this case, there is a tendency of particles in water to build up scale, while scale particles tend to get into solution again. In untreated water, the tendency to build up scale is stronger than those to dissolve, as particles tend to stick to each other. After Scalewatcher treatment, the situation changes: As the particles in water do not deposit any longer, the scale particles will dissolve, one after the other.

Besides the chemical law of mass action, there is a physical aspect, that supports scale removal. Scale is building up layer by layer, piling up more and more. These layers, however, reflect changing water composition over time. While they are quite homogenous in the layer itself, the surrounding layers have a different composition. Therefore the bonding between the layers is weaker than inside a layer. So intermediate layers will be "attacked" first and removal starts there first.

The main effect of the treatment is that smaller and many more crystals with a rotundas shape are formed in the bulk of the water, which will not adhere to pipe walls as long as the water flows. The flowing water will remove old scale layers by sheer mechanical force. The treatment therefore needs flowing water to be effective.

Non flowing water systems are problem areas for this type of treatment, such as dishwashers in restaurants or hospitals and humidifiers in museums or paper factories and evaporators in the sugar Industry, where the juice is concentrated by evaporation. There will be remaining scale, however this will be less and softer so will be easier to clean.

Fire tube steam boilers in the food Industry where it is not allowed to use any chemicals will benefit from the installation of Scalewatcher. The boiler will not be kept scale free for ever as not much water is flowing. However scale will be softer and it takes longer to form.

The pictures below show the way crystals grow in non treated and treated water..

Water containing less dissolved minerals. smaller and many more mineral crystals with a rotundas shape. They will not stick to pipe walls when there is sufficient flow.